"Isso vai ser muito importante para o produtor do futuro. A tecnologia Bio Revolution é, hoje, a chave do sucesso."

Alysson Paolinelli

Ex-Ministro da Agricultura e Diretor da Verde Agritech

These innovative technologies are ingrained in the conception of our products, enabling us to deliver unparalleled results in agricultural practices.

Recent FAO report “State of Knowledge of Soil Biodiversity” highlights the importance in protecting soil biodiversity.

We are the first company to commercialize a mineral fertilizer with added microorganisms in large scale.

Bacillus aryabhattai, widely renowned in agriculture for its multiple benefits, is the first microorganism incorporated into our products.

As the first company to commercialize in large scale a mineral fertilizer with added microorganisms.

Recent FAO report “State of Knowledge of Soil Biodiversity” highlights the importance in protecting soil

biodiversity and presents the solutions that it can provide.

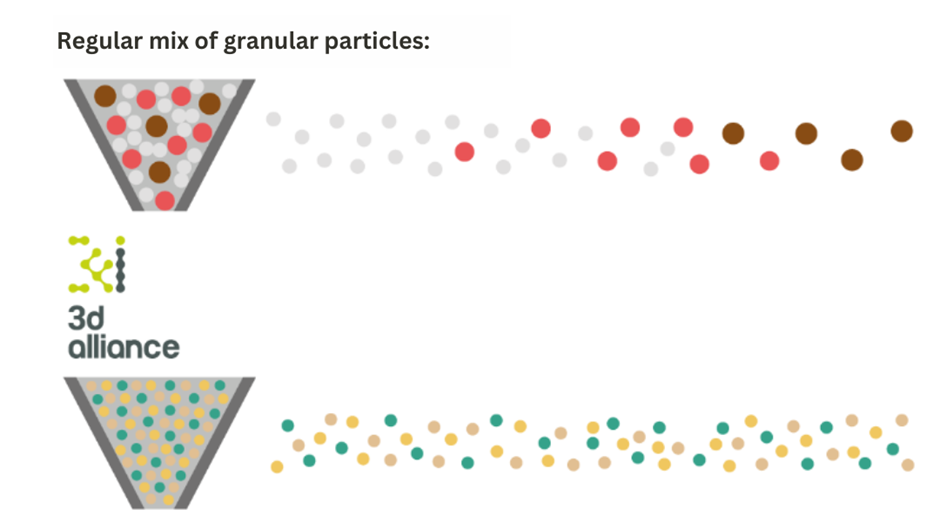

The fertilizers resulting from the mixture are homogeneous and are distributed evenly in the soil, without segregation.

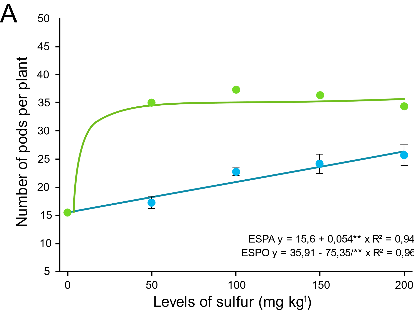

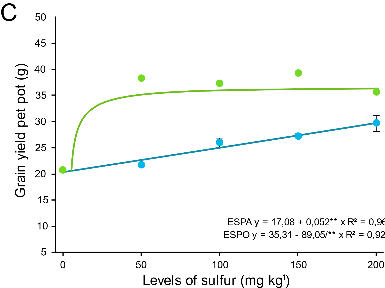

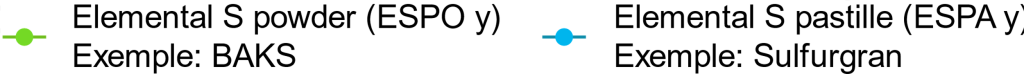

Researchers from the State University of São Paulo conducted a study on soybean crops, revealing that the granulometry of the sulfur source plays a vital role in sulfur availability to plants.

Four sulfur sources were tested: pelleted elemental sulfur, plaster, gypsum, and powdered elemental sulfur (micronized).

The application of micronized sulfur resulted in higher pod count, grain count, and grain yield per pod compared to pelleted sulfur sources.

This demonstrates that smaller particle sizes of sulfur provide a larger contact surface area for soil reaction.

Smaller sulfur particles disperse easily in the soil, enabling better interaction with microorganisms. This leads to increased oxidation rates and improved nutrient availability for plants.

Sulfur absorption and plant development are positively impacted by the smaller particle size, as indicated by the charts showing the interaction effect on soybean pod count (A), grain count (B), and grain yield (C) with different sulfur levels and sources (elementary pastille – ESPA and micronized elementary sulfur – ESPO):

Source: IBANEZ, Thiago Bergamini et al . Sulfur modulates yield and storage proteins in soybean grains. Sci. agric. (Piracicaba, Braz.), Piracicaba , v. 78, n. 1, e20190020, 2021.

"Isso vai ser muito importante para o produtor do futuro. A tecnologia Bio Revolution é, hoje, a chave do sucesso."

Alysson Paolinelli

Ex-Ministro da Agricultura e Diretor da Verde Agritech

Eu vejo como uma revolução, que vai nos permitir usar o K Forte® como veículo para o Bacillus aryabhattai. Parabenizo a Verde Agritech por essa iniciativa."

José Luiz Garcia

Fundador do Instituto de Agricultura Biológica

“Eu acho que agora estamos numa revolução com a Verde Agritech aditivando os Bacillus junto ao fertilizante. É fantástico. Vem atender uma demanda muito importante. Nós degradamos muito a microbiota do solo, então cabe a nós tentar repor essa microbiota.”

Laercio Dalla Vecchia

Campeão Nacional do Desafio CESB de Máxima Produtividade que produziu 118,82 sacas de soja por hectare

We offer a way out of Brazil’s dependency on imported inputs.

Developed in collaboration with the University of Cambridge, Cambridge Tech boosts the benefits of progressive nutrient release for the crops nourished by our products.

Progressive release technology ensures that nutrients remain accessible to plants over an extended period, providing continuous nourishment throughout the crop cycle.

The controlled release of nutrients minimizes leaching, preventing excessive loss of valuable nutrients and optimizing their utilization by plants.

Since progressive release products deliver nutrients over an extended period, a single application per harvest is sufficient, resulting in reduced operational costs.

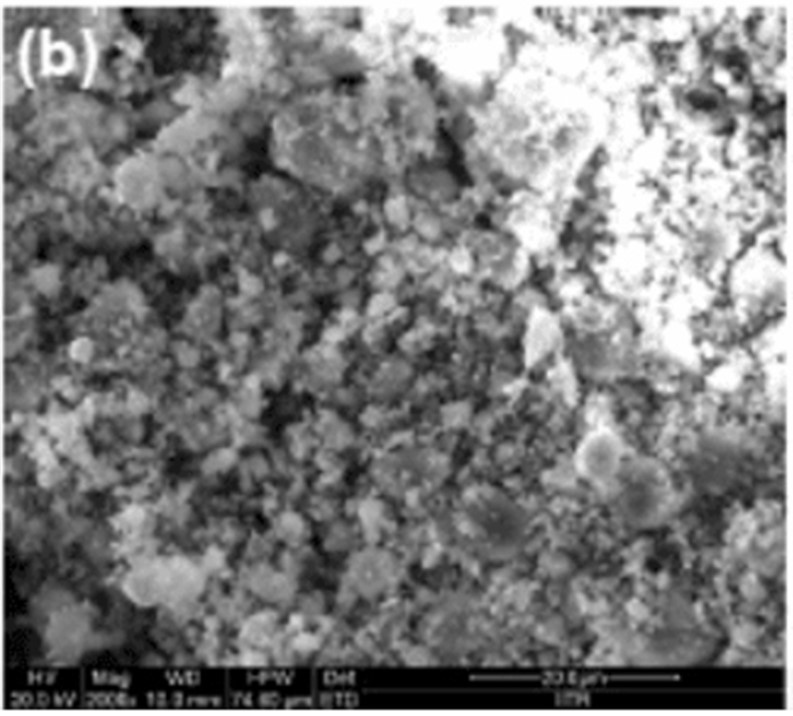

Glauconite particles with an average size of 8 microns

Particles became thinner (4 microns), dispersed in clots, and became more spherical, increasing the surface area.

Source: R. Singla, T.C. Alex, R. Kumar, On mechanical activation of glauconite: physicochemical changes, alterations in cation exchange capacity and mechanisms, Powder Technology, v. 360, 2020, 337-351.

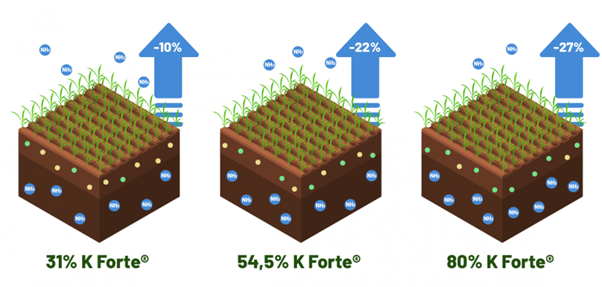

This combination is responsible for the reduction of nitrogen volatilization loss, allowing more agronomic efficiency for farmers and contributing to the reduction of the global warming impacts caused by nitrogen fertilizers manufacturing and application.

However, the production of synthetic nitrogen fertilizers is a significant source of greenhouse gas (GHG) emissions, with fossil fuel mining and transportation, ammonia synthesis and conversion of ammonia to various N fertilizer products.

The application of synthetic N fertilizers is recognized as the most important factor contributing to direct nitrous oxide (N2O) emissions from agricultural soils.

N2O is a potent GHG, with a 298 higher global warming potential in a 100-year timeframe than carbon dioxide (CO2).

Nonetheless, this fertilizer shows low use efficiency under field conditions, due to the high susceptibility to losses, such as ammonia (NH3) volatilization.

Source: Chai, R., Ye, X., Ma, C. et al. Greenhouse gas emissions from synthetic nitrogen manufacture and fertilization for main upland crops in China. Carbon Balance Manage 14, 20 (2019).

Bouwman AF. Direct emission of nitrous oxide from agricultural soils. Nutr Cycl Agroecosyst. 1996;46:53–70.

Faradiella Mohd Kusin, Nurul Izzati Mat Akhir, Ferdaus Mohamat-Yusuff, Muhamad Awang. The impact of nitrogen fertilizer use on greenhouse gas emissions in an oil palm plantation associated with land use change. Atmósfera vol.28 no.4 Ciudad de México oct. 2015.

Yahya, N. Urea fertilizer: The global challenges and their impact to our sustainability. Green Energy and Technology (978981). 2018. p. 1-21.

IPCC (2007): Climate Change 2007: Synthesis Report. 2007. In: Pachauri R.K., Reisinger A. (eds.): Contribution of Working Groups I, II and III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change. Geneva, Intergovernmental Panel on Climate Change.

Pereira, H. S.; Leão, A. F.; Verginassi, A.; Carneiro, M. A. C. Ammonia volatilization of urea in the out-of-season corn. Revista Brasileira de Ciência do Solo, Viçosa, v. 33, n. 6, p. 1685-1694, 2009.

Independent research concluded that the use of our products processed with the N Keeper technology, showed a potential to reduce relative ammonia volatilization between 10% to 27%, depending on the proportion of product employed, when compared to conventional regular use of urea without any of it.

N Keeper allows our products to effectively retain ammonia when used as a calibrated additive in Nitrogen fertilizers.

This combination is responsible for the reduction of nitrogen volatilization loss, allowing more agronomic efficiency for farmers and contributing to the reduction of the global warming impacts caused by nitrogen fertilizers manufacturing and application.

Hence, N Keeper provides a high capacity of ammonia retention, leading to the reduction of nitrogen volatilization loss.

Dust Control provides high efficiency in the application process of K Forte® and BAKS® fertilizers, which have particle size standards above those stipulated by the Brazilian Ministry of Agriculture, with an average particle size of 0.069 mm, equivalent to about 250 mesh.

Dust Control allows for the optimization of crop fertilization, ensuring maximum performance in the application of our fertilizers. The technology enables a slight aggregation effect on the particles, bringing versatility to crop management and reducing drift during application.

The micro particles are easily dispersed in the soil and have enhanced contact due to the ultrafine granulometry of our fertilizers, resulting in uniform application and efficient nutrition.

The result is a complete blend of nutrients with the ideal granulometry to achieve maximum performance in fertilizer application and maximize crop productivity.

As the first company to commercialize in large scale a mineral fertilizer with added microorganisms.